The project aimed at developing a small sized Unmanned Aerial System (UAS) based on the fixed wing platform, having long endurance, in a pusher configuration; capable of both civil and defense applications. The platform was chosen specifically to accommodate future modifications to the design; larger wingspan and heavier payloads.

The developed UAS has long endurance - greater than seven hours, and good all-up weight - about 16 - 21 kilograms, in which payload capacity varies from2-6 kilograms. The UAS propulsion system can be either electrical or gasoline, both mounted in a pusher configuration. The pusher configuration was chosen keeping in mind futuristic application of the UAS in sensitive areas where exhaust fumes from puller engine may affect different environmental sensors. Our UAS is presently operated through a Ground Control System (GCS), with autonomous flight capability using an on-board autopilot that is capable of waypoint navigation and loitering flight; except take-off and landing. The present system is designed and tested for an operational ceiling of 5000 feet from the sea level.

After analyzing the defense and civil scenario, it is identified that the low altitude long endurance tactical section of UAV is the most lacking area. Such UAVs find application in border patrol, search and rescue, traffic monitoring, crowd control, environmental studies, asset monitoring, crop monitoring and re-supply.

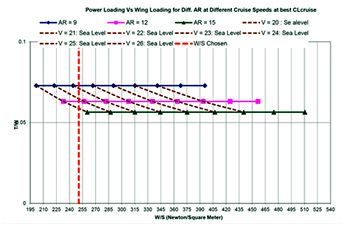

Initially, multiple configurations were designed and tested for attaining the design specifications. The most important of them were the wing loading and power loading, which was extensively studied. The results are summarized in Figure 1.

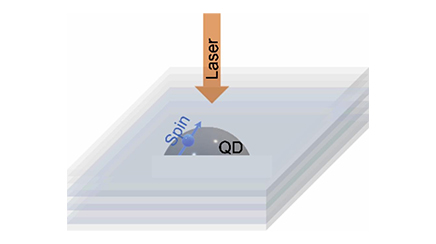

Once the airframe design was finalized, the manufacturing of the airframe was researched for rapid production, maintainability, knock-down for easy transportation to mission locations, repairability, along with rapid instrumentation for conversion to a research platform. Considering all aspects, we decided to use composites, mainly of fibre reinforced plastics, Kevlar, and carbon fibre. For example, the fuselage was made as hollow monocoque structure, made of fiberglass sandwiched with 2mmrohacell. Similar approach was also used for wing manufacturing, where the final surface finish met the aerospace requirements, as shown in Figure 2.

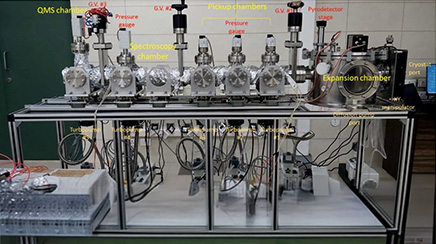

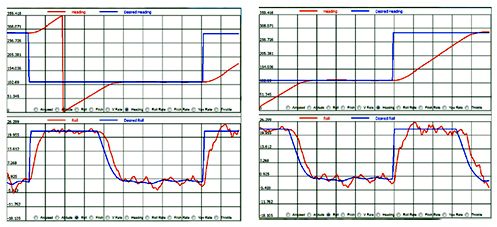

The control system provides integrated miniaturized avionics for autonomous control of micro/mini UAV, which is also capable of automatic take-off, landing, waypoint navigation and steering flight control with manual override. The MIL grade autopilot has integrated INS/GPS and Air data System provide accurate estimates of altitude, velocity and position. The versatile I/O interface provides option to hook up external payloads for user specific requirement. The integrated data link mode provides communication in excess of 20 kms range. Users can dynamically plan mission, monitor critical flight parameters and adjust UAV parameters through an intuitive graphical user interface (GUI). The system performance was characterized and typical outcomes shown in Figure 3.