PI: Krishanu Biswas

Co-PI: Dipak Mazumdar

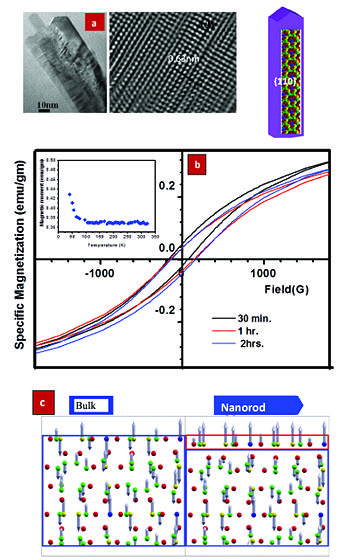

The study of nanocrystalline material is an active area of research in materials engineering, physics, chemistry, biomedical engineering etc., as nanoparticles are thought to hold some keys for solving many of the present and future technological problems. The size- and shape- dependent properties are closely related to important applications of nanoparticles like in chemical sensors, flexible video display etc. Free standing or isolated nanoparticles have been studied extensively in past decades in order to extract their intrinsic properties which are useful for device applications as these are of foremost importance to scientific and technological communities. However, such particles were prepared by chemical synthesis routes. The bulk preparation of such particle is not reported in the literature. It is expected that ball milling at low temperature can be used for such preparation process. Therefore, it is imperative to understand the synthesis of free standing nanoparticles of controlled particle size by ball milling.

Fundamentally, the preparation of free standing nanoparticles is decided by the competition between cold welding and fracturing during ball milling. These two factors strongly depend on the milling temperature. The cryomilling is expected to provide us the answer. The problem basically deals with the synthesis and direct applications of free standing nanoparticles of different materials. Due to their size and stability problem, the nanoparticles aggregate easily because of their high surface energy and also quickly get oxidized. The present research work deals with scientific understanding of the free standing nanoparticles during cryomilling. In fact we aim to probe this theoretical concept in the present project. The present investigation will also study the measurement of strength of cold-weld strength of similar metals at different temperature (from room temperature to low temperature) to probe the above mentioned points. For this joints will be prepared by cold –welding of two plates under pressure in in-house cold welding set up and then strength of the welding joint will be measured.

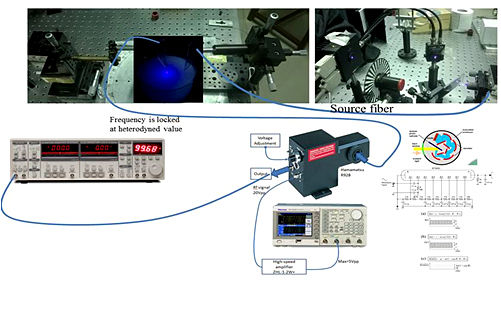

Figure: The modified cryo-mill set up to be used in the present investigation